🚁🚁🚁 𝐓𝐨𝐲 𝐝𝐫𝐨𝐧𝐞 𝐟𝐥𝐢𝐠𝐡𝐭 𝐜𝐨𝐧𝐭𝐫𝐨𝐥𝐥𝐞𝐫 𝐦𝐚𝐧𝐮𝐟𝐚𝐜𝐭𝐮𝐫𝐢𝐧𝐠 𝐬𝐭𝐨𝐫𝐲

Here’s a brief breakdown of the steps I follow to transform a bare board into a fully assembled PCB:

1️⃣ 𝗦𝗼𝗹𝗱𝗲𝗿 𝗣𝗮𝘀𝘁𝗲 𝗔𝗽𝗽𝗹𝗶𝗰𝗮𝘁𝗶𝗼𝗻 (Top Layer): A precise manual (stencil) solder paste application on designated pads.

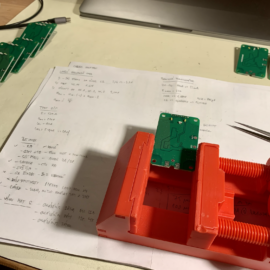

2️⃣ 𝗧𝗼𝗽 𝗟𝗮𝘆𝗲𝗿 𝗖𝗼𝗺𝗽𝗼𝗻𝗲𝗻𝘁 𝗣𝗹𝗮𝗰𝗲𝗺𝗲𝗻𝘁: With the help of a pair of tweezers, components are meticulously placed on their respective solder paste beds.

3️⃣ 𝗧𝗼𝗽 𝗟𝗮𝘆𝗲𝗿 𝗥𝗲𝗳𝗹𝗼𝘄 𝗦𝗼𝗹𝗱𝗲𝗿𝗶𝗻𝗴: The board is put into a reliable reflow oven, where the solder paste melts, forming secure connections.

4️⃣ 𝗦𝗼𝗹𝗱𝗲𝗿 𝗣𝗮𝘀𝘁𝗲 𝗔𝗽𝗽𝗹𝗶𝗰𝗮𝘁𝗶𝗼𝗻 (Bottom Layer): A similar solder paste deposition process for the underside of the board.

5️⃣ 𝗕𝗼𝘁𝘁𝗼𝗺 𝗟𝗮𝘆𝗲𝗿 𝗖𝗼𝗺𝗽𝗼𝗻𝗲𝗻𝘁 𝗣𝗹𝗮𝗰𝗲𝗺𝗲𝗻𝘁: Just like the top layer, components are positioned on the solder paste beds of the bottom layer.

6️⃣ 𝗕𝗼𝘁𝘁𝗼𝗺 𝗟𝗮𝘆𝗲𝗿 𝗥𝗲𝗳𝗹𝗼𝘄 𝗦𝗼𝗹𝗱𝗲𝗿𝗶𝗻𝗴: Another pass through the reflow oven ensures components on the bottom layer are firmly soldered in place.

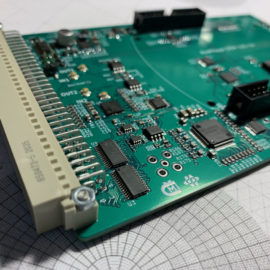

🎉 𝗙𝗶𝗻𝗶𝘀𝗵𝗲𝗱 𝗣𝗖𝗕 𝗔𝘀𝘀𝗲𝗺𝗯𝗹𝘆! The final product: a fully assembled PCB, ready for testing and eventual integration.